Petro-SIM and the SIM Reactor Suite 7.2

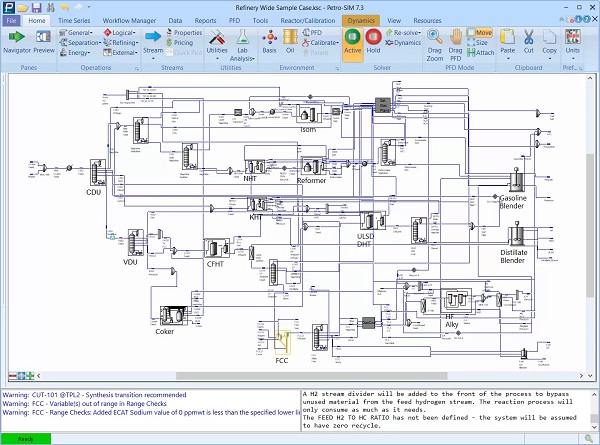

KBC Petro-SIM and the SIM Reactor Suite 7.2 are advanced process simulation tools used in the oil and gas industry for modeling, optimizing, and managing refinery and petrochemical processes.

KBC Petro-SIM and the SIM Reactor Suite 7.2 Description

These tools are developed by KBC, a leading consultancy and software provider in the energy and chemical industries. KBC Petro-SIM and SIM Reactor 7.2 are powerful tools for the oil and gas industry, providing comprehensive capabilities for process simulation, optimization, and management.

By leveraging advanced modeling techniques, real-time data integration, and user-friendly interfaces, these tools help refineries and petrochemical plants achieve greater efficiency, reliability, and profitability. Whether for day-to-day operational improvements or long-term strategic planning, Petro-SIM and SIM Reactor offer the insights and tools needed to succeed in a competitive and dynamic industry.

Features For KBC Petro-SIM and the SIM Reactor Suite 7.2

- Reactor Modeling:

- Comprehensive Reactor Types: Models a wide range of reactors, including catalytic cracking units (FCC), hydrocrackers, reformers, and more.

- Detailed Reaction Kinetics: Incorporates detailed reaction kinetics and mechanisms for accurate simulation of chemical processes.

- Custom Reaction Models: Allows users to develop custom reaction models based on specific catalytic and process data.

- Advanced Kinetic Modeling:

- Reaction Pathways: Detailed modeling of reaction pathways and intermediates to understand complex chemical transformations.

- Parameter Estimation: Tools for estimating reaction kinetics parameters based on experimental data and plant observations.

- Performance Monitoring and Optimization:

- Catalyst Performance: Monitor and optimize catalyst performance over time, accounting for deactivation and regeneration.

- Yield and Selectivity Optimization: Optimize reactor conditions to maximize yield and selectivity of desired products.

- Integration with Petro-SIM:

- Seamless Integration: Fully integrated with Petro-SIM for end-to-end process simulation and optimization.

- Holistic Analysis: Combine reactor models with other process units for a holistic analysis of the entire process.

- Real-Time and Predictive Analytics:

- Real-Time Data Use: Leverage real-time plant data to update reactor models and provide current performance insights.

- Predictive Maintenance: Use predictive analytics to anticipate maintenance needs and optimize reactor operation schedules.

Password For File ” 123 “