CAMWorks ShopFloor 2025 SP4

Download CAMWorks ShopFloor 2025 SP4, which provides advanced digital tools for machinists to utilize digital machining data in partial models, reduce errors, and improve communication between CNC programmers and craftsmen.

CAMWorks ShopFloor 2025 SP4 Description

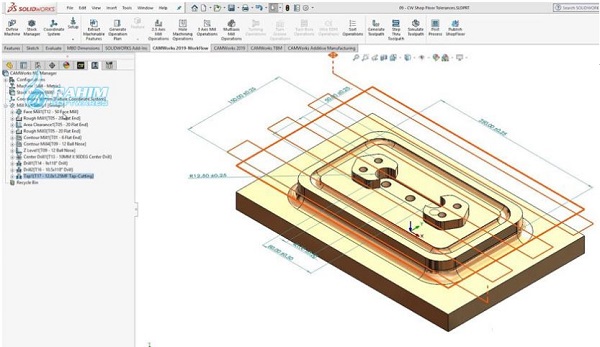

This enables companies to move beyond traditional methods and devise new ways to explain their products, as well as improve quality, increase utilization, and reduce the number of licenses required for their software. Using 3D digital models of CAMWorks ShopFloor software Free Download, extensive data is extracted from the planning section, and provides a tool that machinists can use to supply parts with minimal communication between the planning and construction sections.

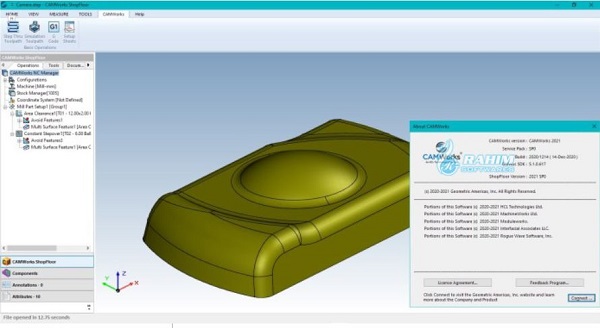

CAMWorks ShopFloor software 2025 provides an entire set of tools for accurate viewing and measurement of 3D parts and assemblies. Digital adjustment sheets and gear lists are often sent with 3D models and CNC programs, and machine builders can simulate a CNC program using 3D simulation.

While much of the core functionality of ShopFloor has been in place for some time, the “2025” references (e.g., “2025 SP3”) in some distribution sources indicate the product is actively maintained, and confirm it remains compatible with contemporary Windows environments and industry expectations. Using a recent version means benefiting from any bug-fixes, updated compatibility (especially with new CAD/CAM outputs), and possibly improved performance or updated file-handling, which is especially relevant in modern shops pursuing digital, “paperless” workflows.

Features Of CAMWorks ShopFloor 2025 SP4

-

3D model/assembly viewer — machinists can rotate, pan, zoom, section-cut, inspect both parts and assemblies; view the native 3D geometry as designed.

-

Support for MBD & PMI data — ShopFloor shows model-based definitions and manufacturing information embedded in the CAD model (tolerances, dimensions, notes, annotations), which helps avoid misinterpretation typical for 2D drawings.

-

Digital setup sheets & tool lists — when parts are ready for machining, operators get the full tooling list, setup instructions, and relevant documents bundled with the model + NC program — reducing confusion or mis-setup.

-

CNC program (G-code) preview & NC Editor — ShopFloor includes a built-in NC (G-code) editor/viewer (often powered by a module such as CIMCO) so machinists can inspect or slightly adjust G-code, do back-plotting, and send to the machine — all without needing a full CAM license.

-

Toolpath simulation & verification

-

Full 3D simulation of the toolpath (material removal, collision check, etc.).

-

Step-through simulation: the operator can walk through each machining operation (or the entire program) step-by-step — valuable for verifying setups and avoiding dry-runs on the actual CNC machine.Revision control / digital data integrity — ShopFloor files act as a “digital container”: the correct 3D model + latest CAM data + NC program + documentation are all bundled. This helps prevent errors like machining outdated versions or relying on outdated drawings.

-

-

Reduction of required CAD/CAM licenses for shop floor — Because machinists only need the ShopFloor license (not a full-featured CAM system), companies can reduce software licensing costs while still delivering rich, digital instructions to the shop floor.

Password For File: 123