FeatureCAM Ultimate 2025

FeatureCAM Ultimate 2025 is a comprehensive software suite designed for automating the Computer-Aided Manufacturing (CAM) process.

FeatureCAM Ultimate 2025 Description

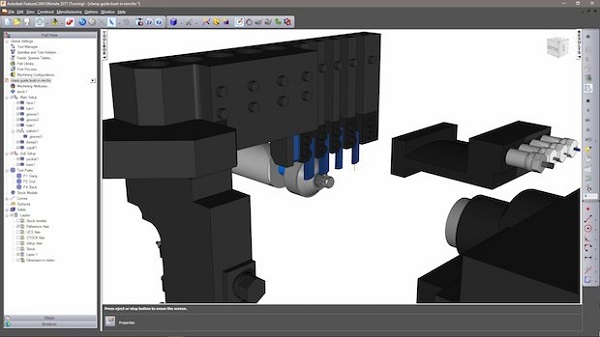

Developed by Autodesk, it is intended to simplify and streamline the process of programming CNC (Computer Numerical Control) machines. FeatureCAM Ultimate 2025 is a powerful tool for automating the CAM process, offering advanced features for milling, turning, and multi-axis machining.

Its automated programming capabilities, combined with robust simulation and verification tools, make it a valuable asset for manufacturers looking to improve efficiency and accuracy in their CNC operations. Whether you’re working with simple parts or complex multi-axis components, FeatureCAM Ultimate provides the tools and flexibility needed to achieve optimal results.

Features Of FeatureCAM Ultimate 2025

- Automated CAM Programming:

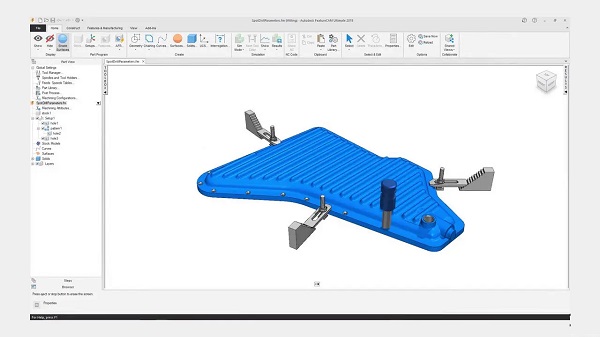

- Feature Recognition: Automatically recognizes and creates toolpaths for holes, pockets, and other features, significantly reducing programming time.

- Adaptive Machining: Uses advanced algorithms to create efficient toolpaths that minimize machining time while maximizing tool life.

- Comprehensive Toolpath Strategies:

- Milling: Supports 2.5D, 3D, and 5-axis milling operations with a variety of toolpath strategies to optimize surface finish and material removal rates.

- Turning: Provides tools for programming turning, grooving, threading, and other lathe operations.

- Mill-Turn: Combines milling and turning operations in a single setup, ideal for complex multi-axis machining centers.

- Wire EDM: Generates precise toolpaths for wire EDM machines, supporting a wide range of machines and controllers.

- Multi-Axis Machining:

- 3+2 and Simultaneous 5-Axis Machining: Supports multi-axis machining strategies for complex parts, allowing for more efficient and accurate machining.

- Toolpath Simulation: Provides real-time simulation of multi-axis toolpaths to detect and avoid collisions and other issues.

- Tool Library Management:

- Customizable Tool Libraries: Create and manage libraries of cutting tools, including custom tool geometries and parameters.

- Automatic Tool Selection: Automatically selects the best tools for the job based on the feature being machined and the available tools.

- Post-Processing:

- Customizable Post-Processors: Supports a wide range of CNC machines and controllers with customizable post-processors to generate machine-specific code.

- Integrated Post-Processing: Seamlessly integrates post-processing within the software, ensuring that the generated code is ready to run on the machine.

Password For File: 123