WISE VisualCAM 16.9

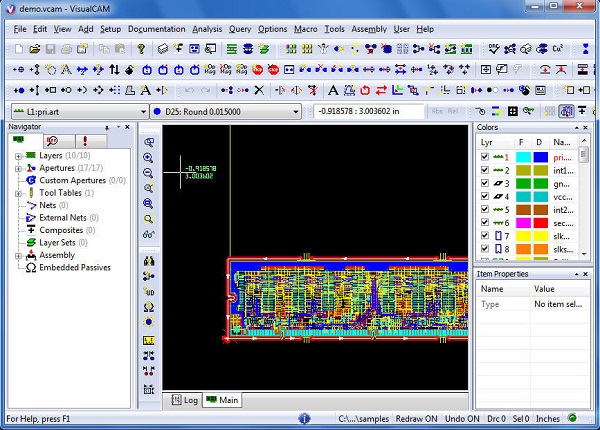

WISE VisualCAM 16.9 Free Download is a versatile and powerful Computer-Aided Manufacturing (CAM) software designed to streamline and optimize the process of creating manufacturing plans from design files.

WISE VisualCAM 16.9 Description

It’s particularly well-suited for Printed Circuit Board (PCB) manufacturing and other detailed fabrication tasks. WISE VisualCAM is a comprehensive tool that bridges the gap between design and manufacturing, ensuring that PCBs and other fabricated products are produced accurately and efficiently. Its robust feature set and ease of use make it a valuable asset for manufacturers aiming to optimize their production processes.

If you are a new engineer, this software provides advanced features in a simple environment for verifying manufacturing and designing circuits. WISE VisualCAM 16 is also suitable for advanced people who need assembly processing capabilities. Whether your role in the project is design or manufacturing, you can use this software to build quality electronic circuits.

Features Of WISE VisualCAM 16.9

Comprehensive CAM Functionality

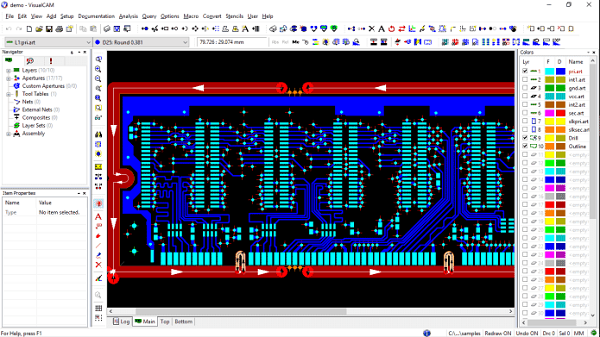

- Gerber File Support: VisualCAM is adept at importing and working with Gerber files, the standard format for PCB designs.

- Drill and Rout Data: Handles Excellon and NC drill files, ensuring an accurate representation of all drilling and routing information.

2. Design Data Verification

- Design Rule Check (DRC): Ensures that the design adheres to specific manufacturing rules and constraints, preventing costly errors.

- Netlist Comparison: Compares the designed netlist against the extracted netlist from Gerber files to identify discrepancies.

- Bare Board Testing (BBT): Prepares data for electrical testing of bare PCBs to verify connectivity and integrity.

3. Advanced Editing and Optimization

- Graphical Editing: Provides tools for manual editing and optimization of design files, including the ability to modify pads, traces, and other features.

- Panelization: Facilitates the creation of manufacturing panels by placing multiple PCB designs on a single panel, optimizing material usage and reducing costs.

- Step and Repeat: Automates the replication of PCB designs within a panel.

4. Manufacturing Preparation

- Tool Path Generation: Generates precise tool paths for CNC machines, ensuring accurate and efficient material removal.

- Solder Mask and Paste Layers: This function creates and edits solder mask and paste layers, which are crucial for the soldering process.

- Custom Stencils: Designs stencils for solder paste application, ensuring precise placement of solder on the PCB.

Password: 123