CAMWorks 2024 SP3

CAMWorks 2024 SP3 is a powerful computer-aided manufacturing (CAM) software solution designed to enhance manufacturing processes by seamlessly integrating with CAD platforms like SOLIDWORKS and Solid Edge.

CAMWorks 2024 SP3 Description

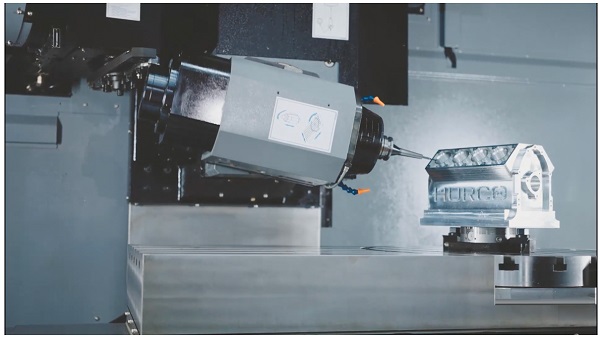

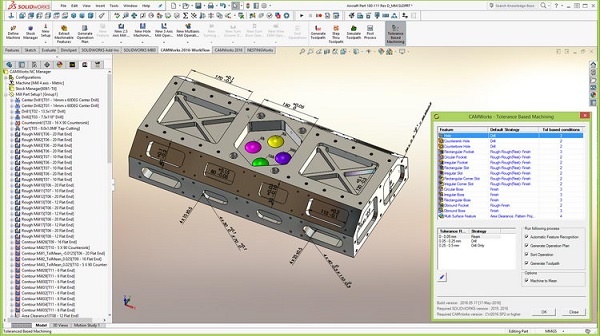

Developed by HCL Technologies, CAMWorks provides advanced toolpath generation, simulation, and automation features that streamline CNC programming and improve machining efficiency. CAMWorks 2024 stands out as a comprehensive CAM solution that leverages advanced technologies to optimize CNC programming and machining processes.

Its seamless integration with popular CAD platforms, coupled with intelligent automation and robust simulation capabilities, makes it an invaluable tool for manufacturers looking to enhance efficiency, precision, and productivity. Whether dealing with simple prismatic parts or complex 5-axis components, CAMWorks 2024 provides the tools necessary to meet diverse manufacturing challenges.

Various software packages are available to meet the needs of users in this regard. Using CAMWorks means the ability to automatically assign tools to machining operations that take into account all tool selection criteria (TechDB ID, Tool Type, and Holder Orientation) and the original tool parameters.

Features Of CAMWorks 2024 SP3

- Seamless CAD Integration:

- Embedded CAM: Fully embedded within SOLIDWORKS and Solid Edge, allowing for a single interface and eliminating data translation issues.

- Feature-Based Machining (FBM): Automatically recognizes and programs prismatic features, reducing programming time.

- Advanced Toolpath Generation:

- High-Speed Machining: Supports advanced toolpath strategies like VoluMill, which optimize tool engagement and reduce machining time.

- 5-Axis Machining: Provides comprehensive 5-axis machining capabilities, enabling the creation of complex geometries with precision.

- Automated Programming:

- Knowledge-Based Machining (KBM): Leverages user-defined machining strategies to automate the selection of tools, speeds, and feeds.

- Automatic Feature Recognition (AFR): Identifies and programs features such as pockets, holes, and bosses automatically.

- Simulation and Verification:

- Full Machine Simulation: Simulates entire machine kinematics, including toolpath, fixtures, and machine movements, to ensure collision-free operations.

- Toolpath Verification: Provides detailed verification of toolpaths to prevent errors and optimize machining processes.

- Intelligent Machining:

- Adaptive Control: Adjusts cutting parameters in real-time based on tool load to enhance tool life and machining efficiency.

- Machine-Specific Post-Processors: Generates optimized G-code for specific CNC machines, ensuring compatibility and performance.

Password for file: “123“