Flownex Simulation Environment 2025 R3

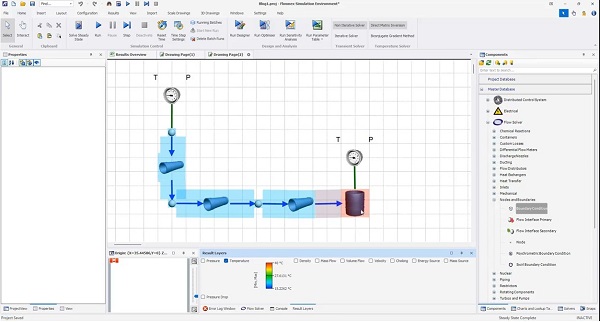

Flownex Simulation Environment 2025 R3 (SE) is a software tool for simulating fluid and thermal systems, particularly at the system/subsystem (1-D / network) level.

Flownex Simulation Environment 2025 R3 Description

It lets engineers model heat transfer, pressure drops, flow rates, transient and steady state behaviors, among other properties. Key uses include HVAC, power generation, gas turbines, spaceflight systems (fuel/cryogenic loops), nuclear systems, data center cooling, and other engineered fluid & thermal networks. The software is developed under quality standards (ISO 9001, etc.) and even has nuclear safety-related compliance.

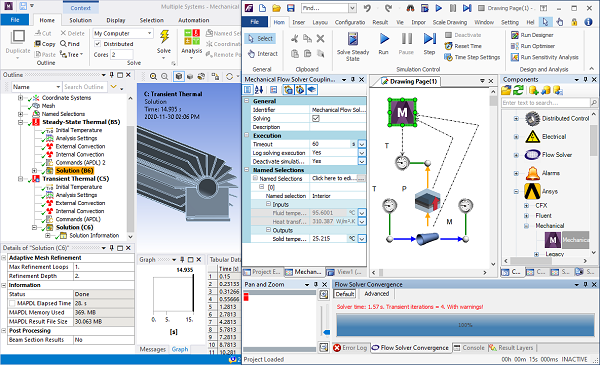

By coupling 1D flow models with 3D heat transfer models in ANSYS Mechanical or CFX, an accurate simulation of turbine blade cooling can be performed. Flownex includes industry-standard pressure drop and heat transfer correlations for common turbine blade features such as turbine blades and fins.

Flownex Simulation Environment 2025 R3 allows designers to quickly see the effects of their design changes on maximum blade temperatures and cooling air flow rates. The preliminary hybrid design requires that a large number of geometric and operational conditions be evaluated and compared.

Especially during this phase, the software is an essential tool for combustor design engineers because it accurately captures important parameters such as the mass flow distribution through the air inlet holes.

Features Of Flownex Simulation Environment 2025 R3

| New Feature | What It Adds / Does |

|---|---|

| Network Builder for Autodesk Revit | Allows extraction of piping/HVAC elements from a Revit model, and building a Flownex network automatically, including automated “healing” of common geometry or export errors. This drastically reduces manual effort for engineers working from BIM / architectural models. |

| Electrical (SPICE DC) Library | Enables modeling of DC electrical circuits inside Flownex, and co-simulation of fluid + electrical networks. Useful for systems where electrical behavior interacts with fluid/thermal behavior. |

| Integration Enhancements with Ansys Mechanical | Better workflow for coupling Mechanical 3D models with Flownex; improved data exchange, more automated geometry and network generation from Mechanical. Co-simulation with Linux HPC clusters is supported. |

| Beggs & Brill Correlation | A new pressure-drop correlation option for two-phase flow, which can improve accuracy in certain multiphase pipeline/flow loop simulations. |

| User-Interface & Usability Improvements | – Changed input grid displays so modified inputs are shown in bold, with the option to reset to the default. – Improved “Result Layers” (legend, activation, editing) so that results overlays are clearer. – PDF help viewer built-in (no need for an external PDF reader), search across help files/tutorials. |

Capabilities & Modules:

Flownex SE includes or supports many modules and capabilities, which make it versatile for various engineering tasks. Some of these are:

- Modeling steady state and transient flow & heat transfer in fluid networks (pipes, valves, heat exchangers, pumps, etc.).

- Handling multi-phase flows (gas/liquid mixtures) where needed.

- Integrations with external tools: Excel, MATLAB/Simulink, Ansys Mechanical / Fluent, FMU / FMI standards, possibly LabVIEW or others.

- Application in many industries: spaceflight, gas turbine, power generation, hydrogen systems, data centers, nuclear, HVAC, and academic / teaching.

System requirements:

- Windows 7/10.

- CPU: Quad Core i7.

- RAM: 16GB.

- Hard Disk: 5GB free hard drive space.

Password For File ” 123 “