GibbsCAM 2025

GibbsCAM 2025 Free Download is a powerful, user-friendly computer-aided manufacturing (CAM) software designed to simplify and optimize the programming of CNC (Computer Numerical Control) machines.

GibbsCAM 2025 Description

Developed by Gibbs and Associates, a Cimatron Group subsidiary, GibbsCAM 2025 is renowned for its intuitive interface and robust capabilities, making it suitable for a wide range of manufacturing applications. It supports various CNC machining processes, including milling, turning, mill-turn, multi-task machining, and wire EDM.

GibbsCAM 2025 is widely used in industrial designs and is very suitable for advanced and very complex machining such as multi-directional machining and high-speed machining. The simplicity of working with the software and its high speed has made it popular among CAM software.

Features Of GibbsCAM 2025

- User-Friendly Interface:

- Intuitive Design: GibbsCAM’s interface is designed to be intuitive and easy to navigate, reducing the learning curve for new users while providing powerful tools for experienced machinists.

- Customizable Workspace: Users can customize the workspace to suit their workflow, with dockable toolbars and customizable menus.

- Comprehensive Machining Solutions:

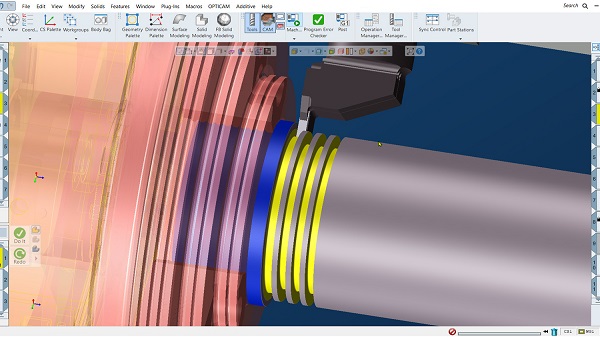

- Milling: Supports 2.5D, 3-axis, and multi-axis milling, with advanced capabilities for high-speed machining and complex surface machining.

- Turning: Provides comprehensive turning solutions, including support for single-turret and multi-turret machines, as well as live tooling and sub-spindle operations.

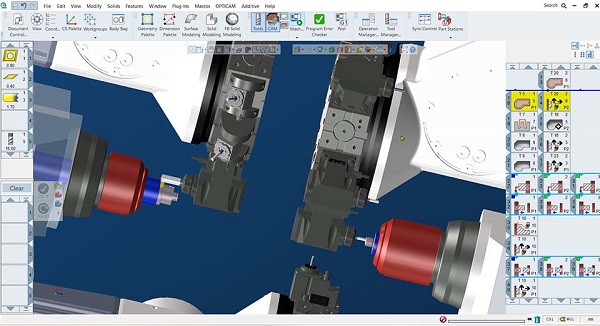

- Mill-Turn: Combines milling and turning capabilities in a single environment, ideal for multi-tasking machines that require synchronized operations.

- Multi-Task Machining (MTM): Supports complex multi-task machines with multiple spindles and turrets, allowing simultaneous operations to improve efficiency.

- Wire EDM: Provides precise control for wire electrical discharge machining, supporting both 2-axis and 4-axis wire EDM operations.

- Advanced Toolpath Strategies:

- Adaptive Milling: Utilizes high-efficiency toolpaths to reduce cycle times and extend tool life.

- 5-Axis Machining: Supports simultaneous 5-axis machining, enabling the production of complex parts with fewer setups.

- VoluMill: An integrated high-speed machining strategy that optimizes toolpaths for faster and more efficient material removal.

Password For File ” 123 “