CAMWorks 2025 SP0

CAMWorks 2025 SP0 is a state-of-the-art CAM (Computer-Aided Manufacturing) software developed by HCL Technologies. It integrates seamlessly with SOLIDWORKS and other CAD platforms to streamline the design-to-manufacturing process.

CAMWorks 2025 SP0 Description

CAMWorks 2025 offers advanced features and enhancements aimed at improving machining efficiency, precision, and ease of use. CAMWorks 2025 is a powerful and versatile CAM solution that enhances the manufacturing process through advanced automation, precision, and efficiency.

Its seamless integration with CAD platforms, comprehensive machining strategies, and user-friendly interface make it an invaluable tool for manufacturers aiming to optimize their operations. Whether dealing with simple parts or complex geometries, CAMWorks 2025 provides the tools and features necessary to achieve high-quality results, reduce costs, and improve productivity in the manufacturing environment.

Various software packages are available to meet the needs of users in this regard. Using CAMWorks means the ability to automatically assign tools to machining operations that take into account all tool selection criteria (TechDB ID, Tool Type, and Holder Orientation) and the original tool parameters.

Features Of CAMWorks 2025 SP0

- Seamless CAD Integration:

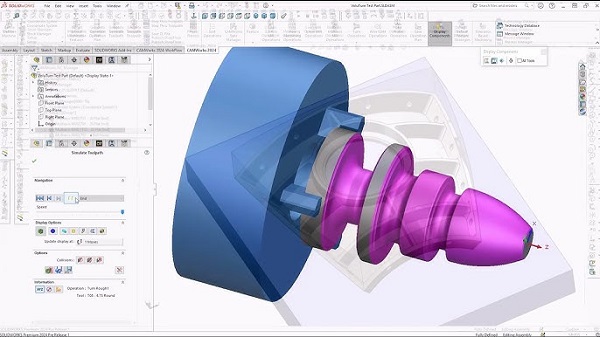

- SOLIDWORKS Integration: CAMWorks integrates directly with SOLIDWORKS, allowing for seamless transitions from design to manufacturing within a single environment.

- Feature-Based Machining: Automatically recognizes and programs machining operations based on the CAD model’s features, reducing programming time.

- Advanced Machining Strategies:

- 3-5 Axis Machining: Supports 3-axis, 4-axis, and 5-axis milling operations, providing flexibility for complex geometries and intricate parts.

- Turn-Mill and Swiss Machining: Offers comprehensive support for turn-mill and Swiss-type machines, enhancing versatility for various manufacturing needs.

- Automated Toolpath Generation:

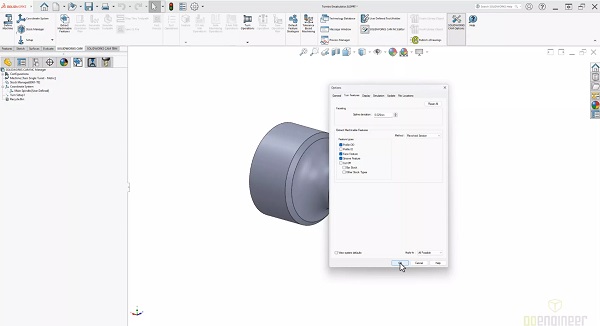

- Automatic Feature Recognition (AFR): Identifies and defines prismatic features automatically, streamlining the toolpath generation process.

- TechDB™ (Technology Database): Stores machining strategies and best practices, allowing for the reuse of proven methods and reducing programming time.

- Simulation and Verification:

- Full Machine Simulation: Provides accurate simulation of the entire machining process, including toolpath verification and collision detection.

- G-Code Verification: Ensures the accuracy of the generated G-code, preventing errors and reducing the risk of machine damage.

Enter Password For Rar File: “123“